Chamotte Brick

2.Al2O3 is 30%-45%,SiO2 is 50%-65%,and a small number of alkali metals,alkaline earthmetal oxides TiO2,Fe2O3.

3.Mineral composition is mullite, quartz and glass phase.

4.Refractoriness is 1580-1750℃, refractoriness under load is 1250-1450℃,

5.Low line expansion coefficients,good thermal shock resistance,strong ability to resist erosion acid slag.

6.Working temperature:less than 1350℃.

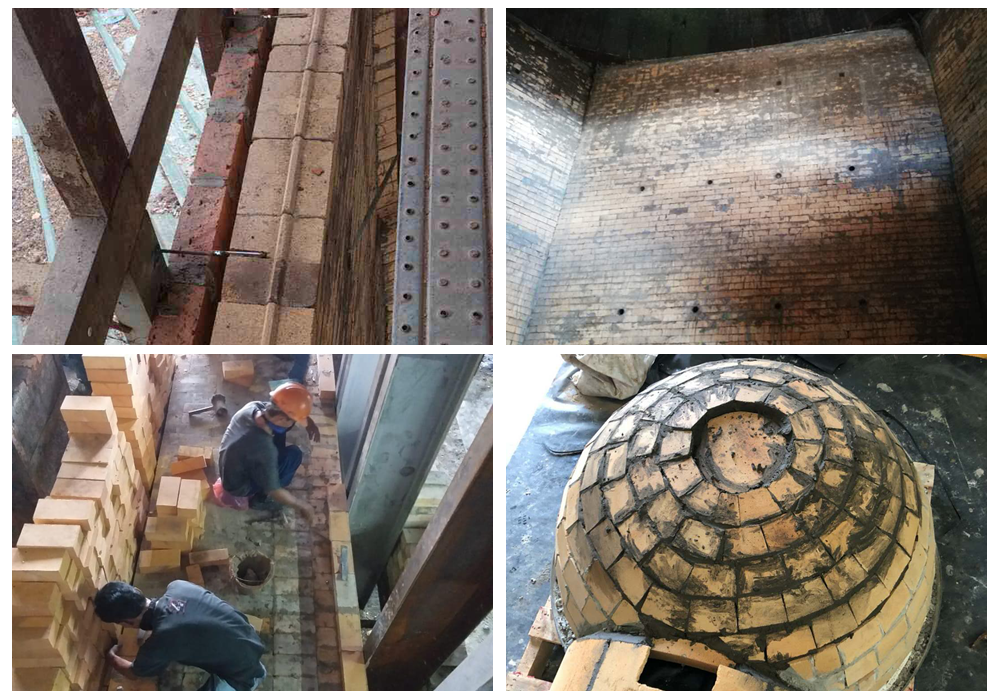

Ruisen can manufacture a series of SK chamotte bricks,including SK30,SK32,SK34,SK35.

1.High refractoriness: Its refractoriness is as high as 1750 degrees Celsius.

|

We also can make brick according to customers’ drawing and requirements. |

|||||

|

Iron &steel making industry |

|

|

Non-ferrous Metal industry |

|

|

Cement kiln,glass kiln,ceramic kiln,lime kilns,kiln car,tunnel kiln,rotary kiln |

|

|

Energy&Incineration

|

|

|

Others |

1.Pallet+Paper or Steel angle bead+Paper board +Plastic or Steel belt +Plastic film

(1)Wooden pallet size:Usually0.92*0.92m(standard brick),but 1*1m (special shape brick)at most,

(2)Load weight of each pallet:Usually 1.5-1.7Tons,but 2.0 Tons at most.

(3)20 Foot Container can be loaded 25-26Tons at most,about 13-16Pallets.

2.Can make the package according to customer's requirements.